FRP Molding Hydraulic Press Machine Boat Mold

Basic Info

Model No.: Yz32

Product Description

FRP Molding Hydraulic Press Machine

FRP is known as fiber reinforced plastic, which is customarily called FRP in China. It is a composite material composed of synthetic resin as a matrix material and glass fiber and its products as reinforcing materials.

Glass fiber and resin and auxiliary materials.

Glass fiber is a reinforcing material, and the choice of this material is the main reason for determining the difference in performance of FRP, and it is also one of the most critical. The most commonly used glass fibers are alkali-free fibers and medium-alkali fibers. Almost all of the performance of medium alkali fiber is worse than that of alkali-free fiber, but the acid resistance is better than that of alkali-free fiber and the price is lower. The glass fiber products mainly include: glass fiber, glass fiber felt, continuous felt, surface felt, knitted felt, composite felt, glass fiber cloth, glass fiber belt and the like.

FRP Molding Hydraulic Press

Resin is a matrix material, and different types of resins can be selected according to the special requirements of various products. Commonly used unsaturated polyester resin, epoxy resin, vinyl ester resin. The unsaturated polyester resin has small viscosity, good wettability, easy elimination of bubbles, and the gel time can be adjusted and controlled as needed, the process performance is the best, and the relative price is also low, so although the strong rigidity is lower than the epoxy, the curing shrinkage The rate is also large, but it is still widely used. Epoxy resin has strong adhesion and is used for high strength FRP products. However, the viscosity is high, the process performance is poor, and the price is relatively expensive. Vinyl resins are widely used in the field of anticorrosion mainly because of their superior corrosion resistance and temperature resistance. Others include phenolic resins, furan resins and some high performance resins. Phenolic resins have recently received extensive attention due to their superior flame retardancy.

Main excipients: release agent, curing agent, catalyst, sealer, UV light stabilizer, clean mold water, gel coat, etc.

The pultrusion process is a method for continuously producing composite profiles by impregnating the crepe-free glass fiber rovings and other continuous reinforcing materials, polyester surface felts, etc., and then maintaining the shape of the cross-section. And it is continuously discharged after molding in the mold, thereby forming an automated production process of the pultrusion product.

The application of FRP composites in the field of civil engineering is growing rapidly. It can be used for seismic and reinforcement reinforcement of columns, walls, beams, slabs and panels. New reinforcement components, structural forms and structural systems are also being researched, developed and applied.

1. Construction Engineering

Structural design is shifting to performance-based design, and structural and material performance requirements are also increased. FRP materials have been used in the construction of new structural frames to improve their structural performance, and have also been used extensively in the repair and reinforcement of old civil buildings.

2. Geotechnical engineering

FRP fiber composites have good corrosion resistance under long-term harsh geological conditions, and have been widely used in reinforced soils; FRP composites are easily cut by excavation tools, so they can be used for shield concrete to dig concrete walls and soil nails of shafts. Composite anchors for temporary support, such as steel anchors, can cause breakage of the excavator head. Due to its low price, easy installation and strong durability, GFRP composites have been used for alternating wet and dry retaining walls, foundation anchors and shotcrete ribs.

3. Bridge engineering

The application of FRP composites to bridge engineering began in the late 1970s and early 1980s. Cables used as suspension bridges and cable-stayed bridges, prestressed tendons in prestressed concrete bridges, can even be used in the entire bridge system; in addition, there are applications in bridge reinforcement.

4. Marine structure and offshore structure

Corrosion problems of marine structures and offshore structures have been prominent, especially for steel structures. Therefore, FRP with good corrosion resistance can solve this problem well and has a good development prospect. The marine reinforced concrete structure under construction adopts the thickest concrete protective layer (generally about 150mm, which is equivalent to more than 5 times of the protective layer of the terrestrial concrete structure) and anti-corrosion measures. It also has only 15 years of corrosion resistance to the internal steel. Left and right, this is far from the durability requirements of permanent or semi-permanent marine structures. The use of FRP concrete or FRP-concrete composite structure can fundamentally solve the corrosion problem of steel (steel) in marine engineering, and its significance is self-evident.

Technical parameter

Model unit Yz32-40 Yz32-63 Yz32-100 Yz32-160 Yz32-200 Yz32-250 Yz32-315 Yz32-500 Yz32-630 Yz32-800 Yz32-1000 Yz32-1600 Yz32-2000 Yz32-3150 Nominal Force KN 400 630 1000 1600 2000 2500 3150 5000 6300 8000 10000 16000 20000 31500 Ejection force KN 63 100 250 250 400 400 630 1000 1000 1250 1250 1600 2000 3150 Max working pressure of liquid Mpa 26 25 25 25 25 25 25 25 25 25 25 25 25 25 Max. open height mm 400 600 800 900 1000 1000 1250 1400 1500 1500 1500 1600 1800 2500 Slider stroke mm 300 400 600 700 700 700 800 900 900 900 900 900 1000 1200 Ejection stroke mm 140 160 200 250 250 250 300 300 300 350 350 450 450 500 Slide speed Down mm/s 40 40 100 100 100 120 120 120 120 120 120 150 150 300 Pressing mm/s 8~15 8~15 8~15 8~15 8~15 8~15 8~15 8~16 8~17 8~18 8~19 8~20 8~21 8~22 Return mm/s 60 60 80 80 80 80 90 80 80 80 100 120 120 250 Table size Left-right mm 350 450 600 800 800 800 1200 1400 1600 1600 1800 1800 2000 2800 Front-back mm 350 420 600 700 800 800 1200 1400 1600 1600 1600 1600 2000 2000 Overall dimensions Left-right mm 1200 1300 2000 2200 2200 2200 3300 3500 3700 3700 4000 4200 4500 5800 Front-back mm 700 800 1000 1000 1200 1200 1600 1600 1800 1800 1800 2000 2000 2000 Height mm 1930 2350 3200 3300 3500 3700 4800 5000 5300 5700 5800 6000 6500 8200 Motor power KW 3 5.5 7.5 15 18.5 18.5 22 37 37 44 60 90 134 180

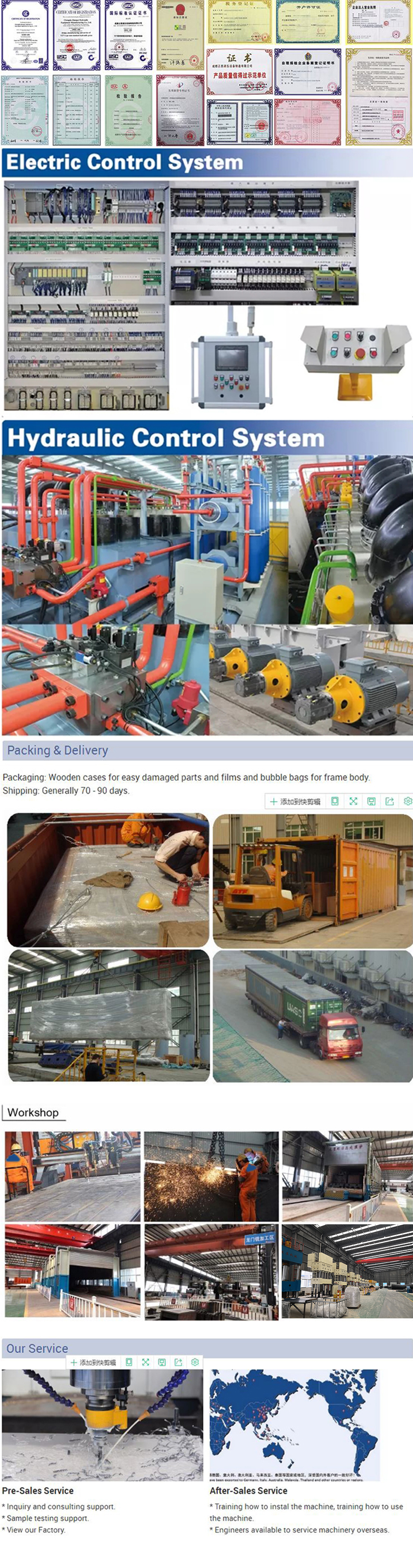

Certificate

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 70 - 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Product Categories : SMC-BMC-GMT > FRP Molding Hydraulic Press